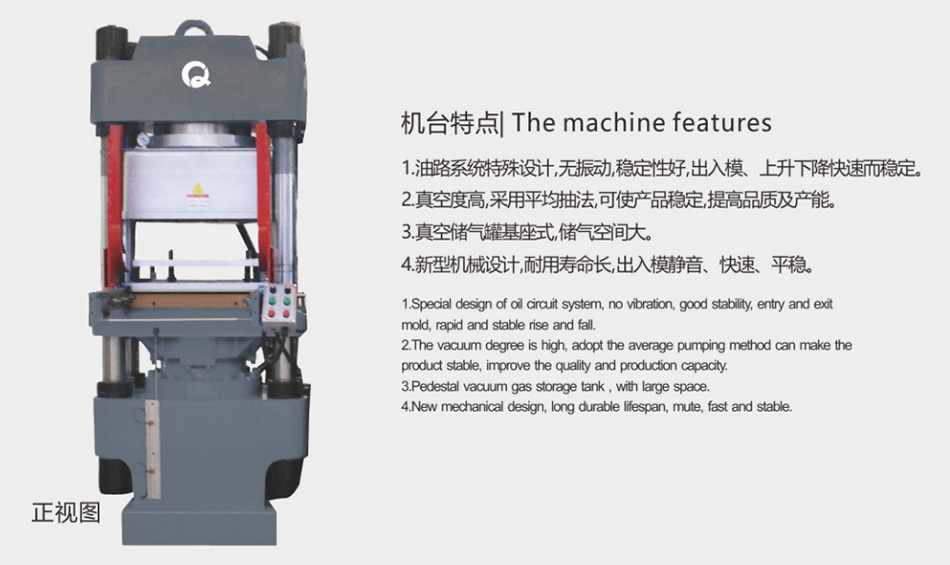

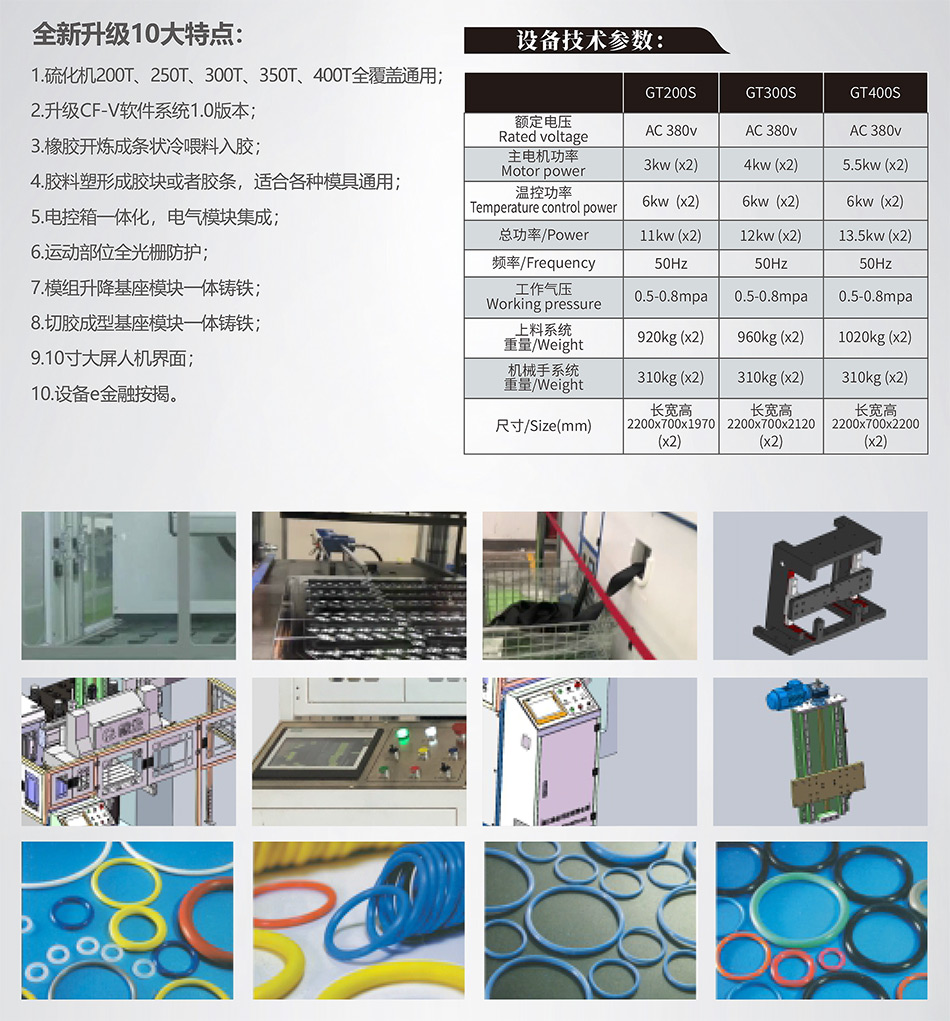

Machine Features

1、Comprehensive internationalization and standardization for parts and components.2、The mechanical design of the durability of the machine.

3、Ion nitriding treatment of high wear-resistant plane.

4、The temperature distribution reaches the high standard of ±2℃.

5、The precision of the exhaust gas can reach 100%.

6、Stable mute oil circuit design.

7、Excellent graphical operation instruction and maintenance manual.

8、The cylinder base adopts 3D computer mechanical analysis, auxiliary structure design, casting molding, strengthening plane accuracy and structure, and maintaining the lifespan of the machine. 9、The scaffolding is designed with square steel beam structure to ensure the stability of the machine.

10、The pressure control is beyond the conventional pressure gauge control, and the pressure sensor is used to control the pressure to be more accurate.

11、The powerful and convenient Siemens electronic control system is perfectly combined with the high efficiency and stable hydraulic system.

Remark

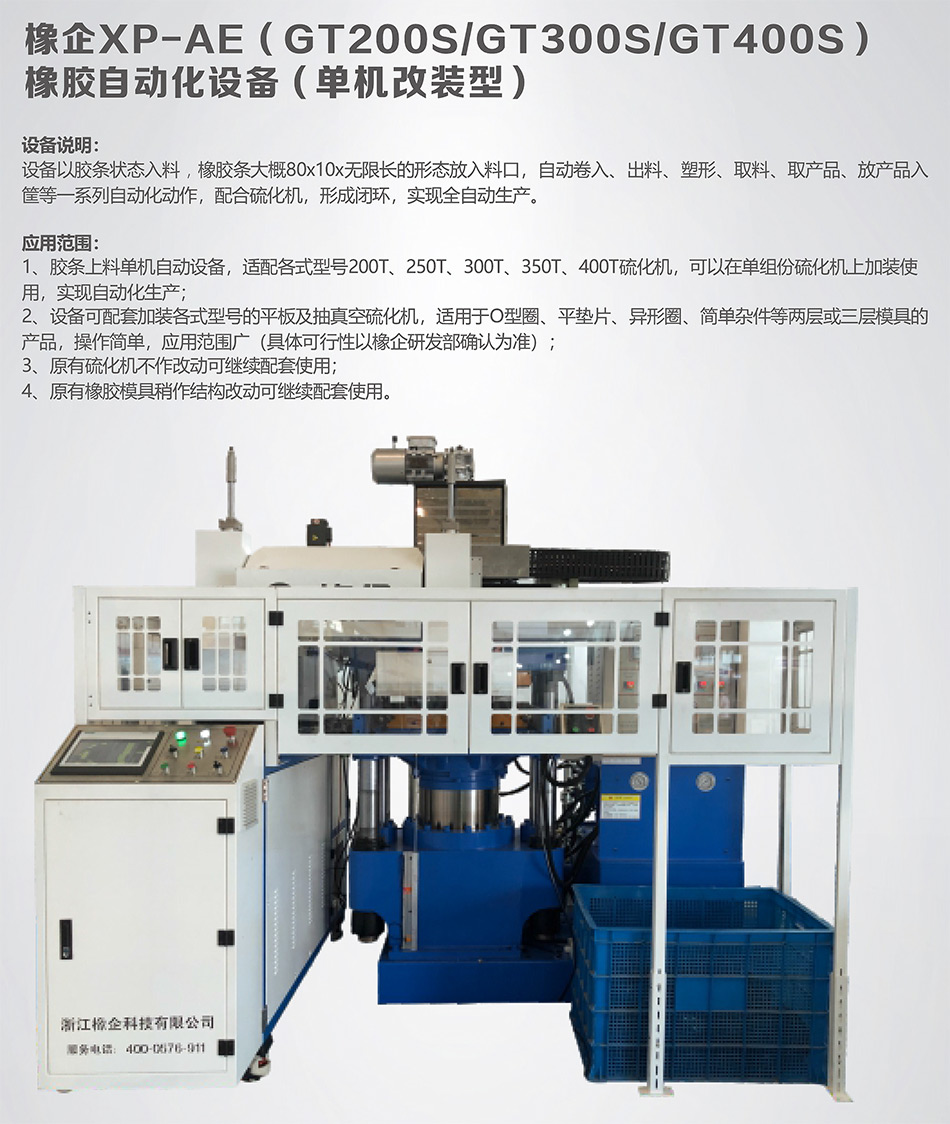

1. Due to the particularity of rubber products, the equipment has different requirements for product structure, rubber characteristics and other indicators, please consult to determine the appropriate model.

2. Accept other products to automatically produce non-standard custom equipment (the specific feasibility and scheme is confirmed by the R&D department of rubber company).

3. Device parameters or configuration updates are subject to further notice due to progress in technology.

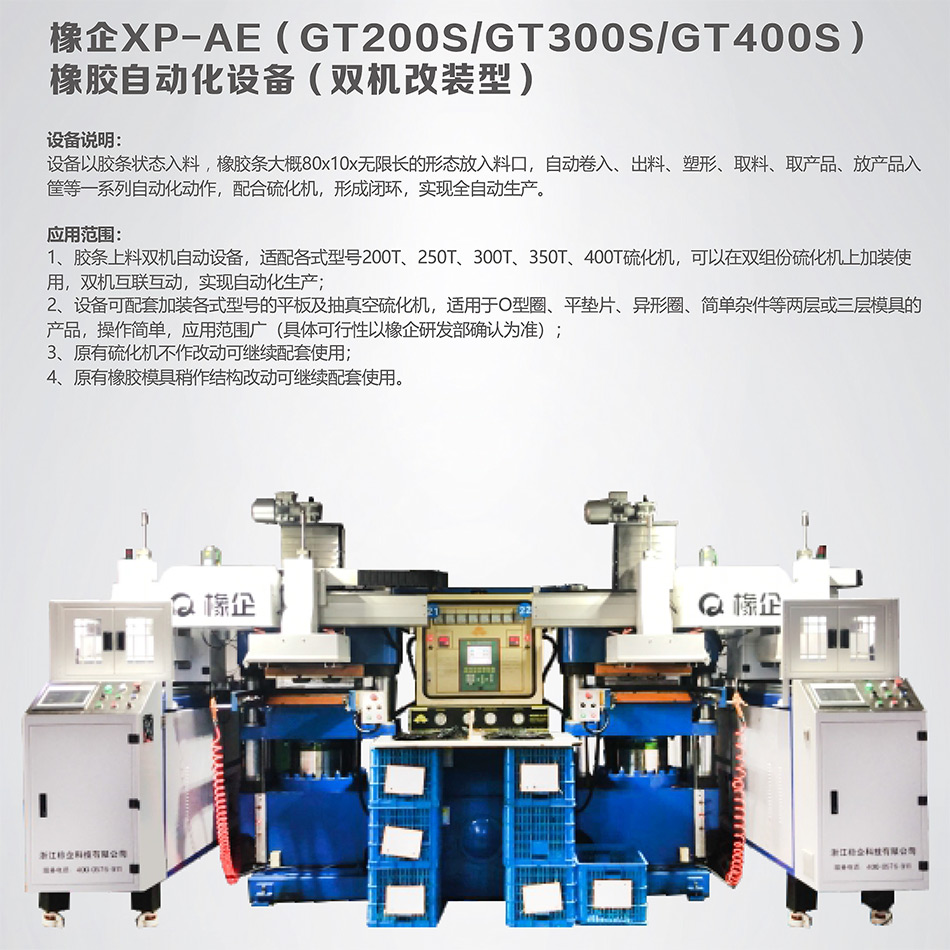

4. The XP-AE series rubber full-automatic vulcanization system is mainly suitable for products of two-layer mould structure type such as O-ring and flat gasket.

5. The company has the final interpretation right of equipment and technical solutions.

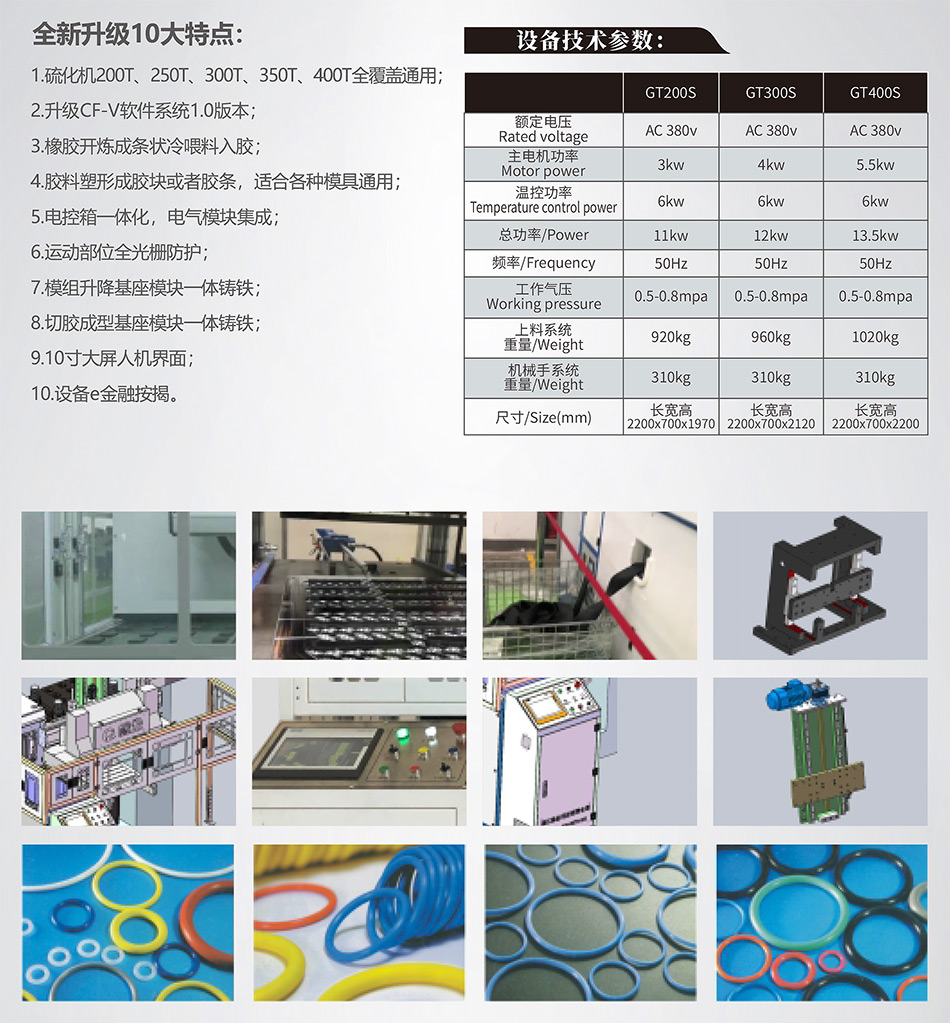

Device Parameters

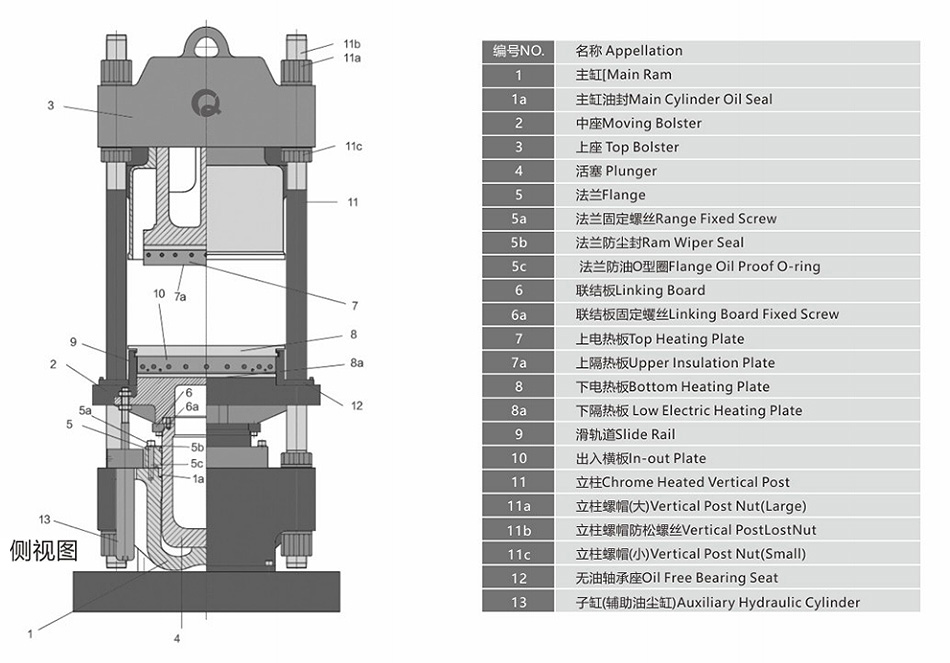

Vulcanizing Main Engine

Electric Control System

• 10 "ーTFT touch color screen input and display;

• High performance processor;

• All motion and temperature closed-loop control OF (X) line functions, action sequence set arbitrarily;

• Real-time on-line alarm reminder and error prompt;

• Ergonomic operation button;

• Varied interface input and software module extension;

• Easy to understand and operate, real-time curve state tracking;

• The periodic analyse improves and optimizes the well operation interface of each process, which is easier to operate;

• Ethernet interface for remote online detection and centralized factory management.

• The electrical components adopt a full set of Siemens products, the matching and compatibility are more powerful;

• EU CE standard, reasonable layout, safe and reliable;

• Modular call, can be selected flexibly through functional control;

• Self-diagnosis of faults;

• The system can accept functional upgrades and additional device options;

• No material detection, broken material detection.

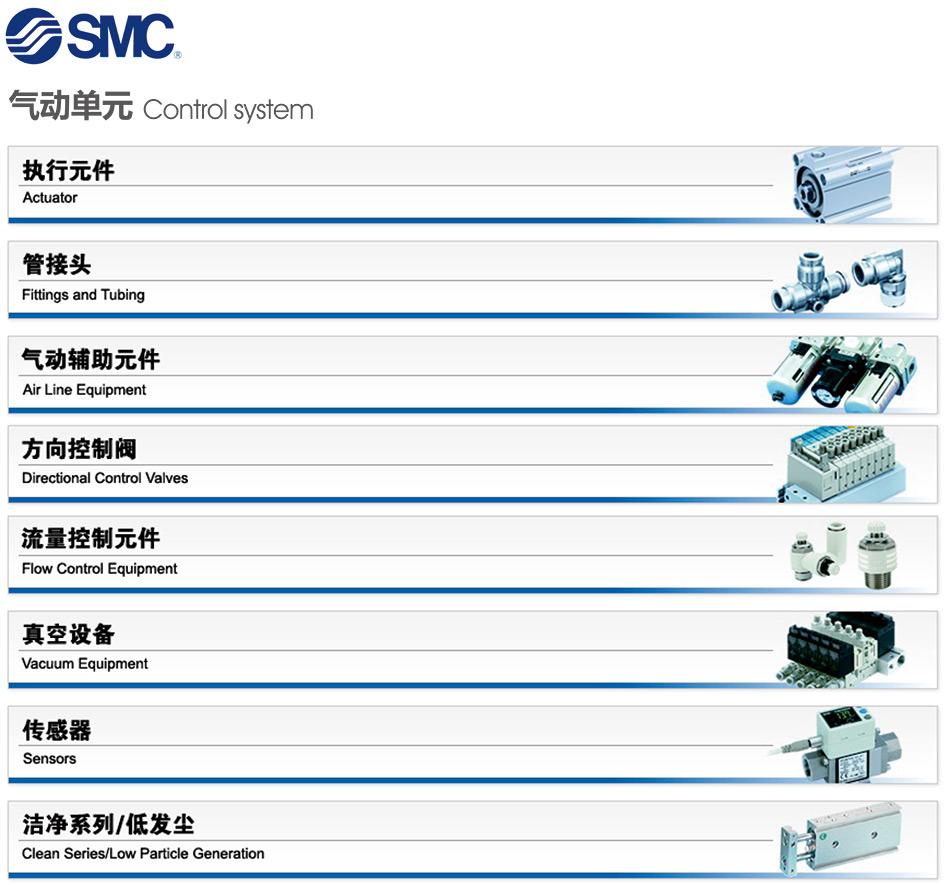

Motion System

The whole machine is equipped with Japanese SMC cylinder, joint, Korean WON linear guideway, Taiwan silver wire rod, Siemens high efficiency motor,International first-line brand to ensure the smooth operation of the machine, accurate movement, durable.

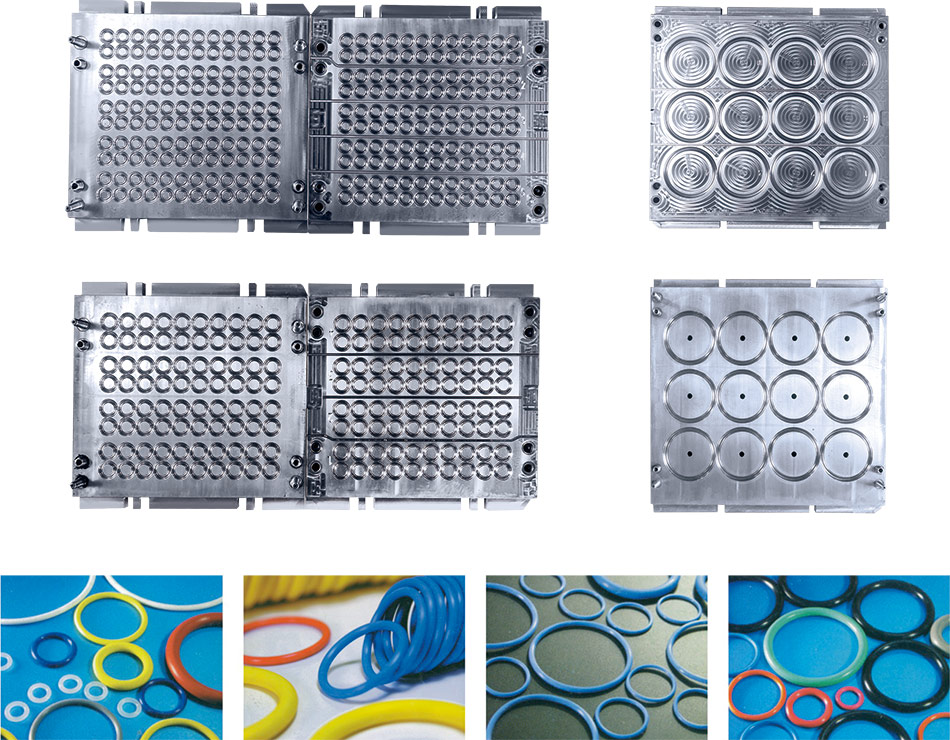

Precision Mold

Based on rich experience and the close cooperation of the global design team, high precision and high standard processing and material processing ability, we can provide you with international first-class rubber mold. The mould can best match the machine capacity and production process in order to maximize the benefit, improve the production capacity and reduce the cost of a single piece. Taizhou Weibang mold matching to provide excellent rubber molding and cold runner system, in the process of pursuing profit for customers, we are keeping study all kinds of different needs of rubber molding industry.

Lab And Testing

The difference of rubber formula properties is the key factor that puzzles the quality of rubber products, and it is also the bottleneck that restricts the high-end development of rubber enterprises. Xiangqi Lab center is equipped with 400T injection molding machine, 200T injection press, 300T vacuum vulcanizing machine, 200T flat plate vulcanizing machine, 50T test film vulcanizing machine, Taiwan Yixin projector, 2.5th unit image measuring instrument, Sinfeng low force measuring caliper, Japan. South Korea imported rubber sulfur meter, Mooney viscometer, rubber tension machine and other complete sets of special testing equipment, and provide a variety of rubber physical and chemical properties testing, technology and service one-stop solution, care for the whole process.

Mobile

Mobile Add: No.2338-2 Jiaobei Road Jiaojiang District

Add: No.2338-2 Jiaobei Road Jiaojiang District